Lindab’s revolutionary ultrasound technology enters the world of wireless connections

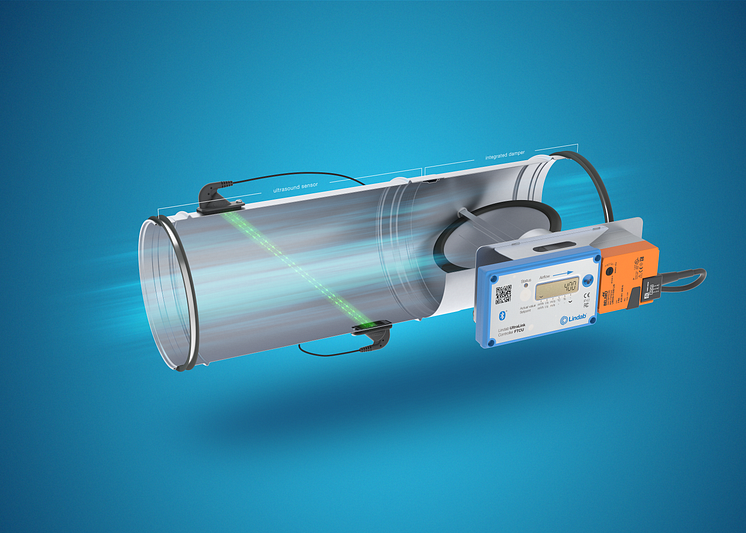

In 2015, Lindab introduced a revolutionary product to the ventilation industry. Using ultrasound sensors, Ultralink was able to perform precise measurements of temperature and airflow in ventilation systems, while also reducing energy consumption for the user.

“The next step was to implement wireless communication using Bluetooth technology. But we’re not stopping there,” says Torbjörn Bruzelius, Product Manager for ventilation products at Lindab.

For a long time, demand controlled ventilation has suffered from two major problems. Not only have measurements not been sufficiently accurate, but it has also not been possible to measure low airflow rates. However, Lindab’s ultrasound technology has helped to solve these problems.

“Previously, ultrasound has been used to perform measurements in gas and water pipelines. But the technology was entirely new to the ventilation industry,” explains Torbjörn Bruzelius.

Ultralink still offers unique advantages today. It is able to perform highly accurate measurements at velocities as low as 0.2 m/s and even lower, and it is therefore the only product able to measure such low velocities with a high degree of accuracy. Furthermore, Ultralink is impervious to dirt.

“All other existing forms of technology that are used to perform measurements are affected by dirt, which impacts measuring accuracy. Ultralink, on the other hand, is not affected at all,” asserts Niclas Ivarsson, R&D at Lindab.

A constantly developing product

Over the years, the company has been working on developing Ultralink and further revolutionising the product.

First, the product was able to measure accurately at low flow rates, and later it gave users the opportunity to control the ventilation system. The third step was to implement wireless communication with the help of Bluetooth. This enabled users to easily control the product using an app.

“We are also looking at how this technology can be used to measure other parameters in the room. Currently, it can be used to measure temperature, airflow and velocity. But in the long run, we also want Ultralink to be able to monitor more variables in the room that it serves,” says Niclas Ivarsson.

Ultralink is now also able to perform measurements in ventilation systems of all standard sizes from 100 mm to 630 mm.

“The goal is for this technology to spearhead the development in ventilation system measurement in the future. The aim is to improve efficiency in the room in order to utilise demand controlled ventilation in the best possible way,” declares Torbjörn Bruzelius.

Contact

Torbjörn Bruzelius

Product Manager Ventilation Products

Mobile: +46 70 3185240

Email: torbjörn.bruzelius@lindab.com