Decarbonised steel

At Lindab, we can offer decarbonised steel with a significantly lower CO₂ footprint compared to traditional steel. Within this concept, there are two main categories: Recycled steel and Near-zero steel.

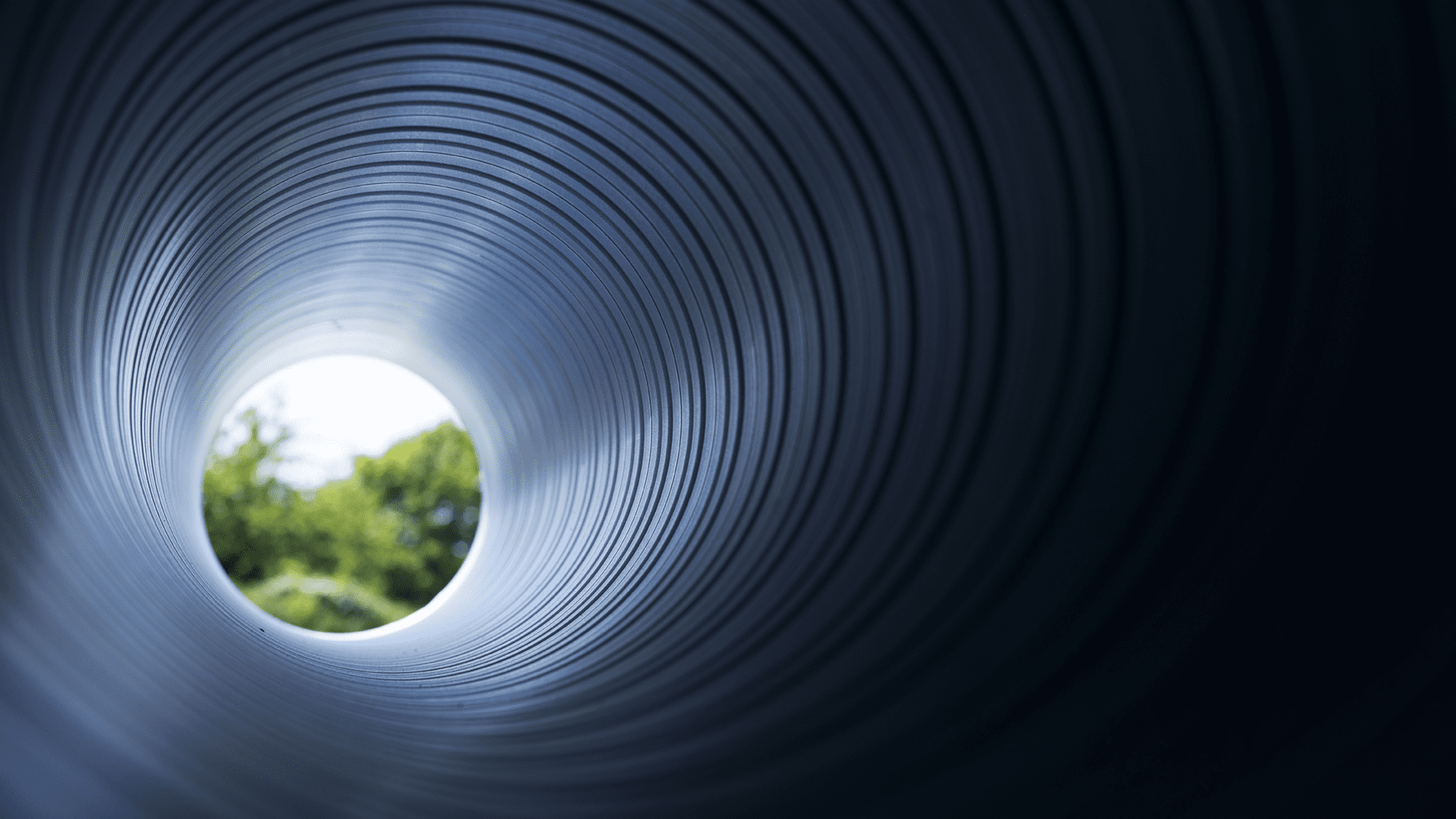

Steel is central to Lindab's products and accounts for a large share of our environmental impact. By working closely with our suppliers and using innovative technologies, we can offer steel products with substantially lower emissions – without compromising on quality or performance. A ventilation duct remains a ventilation duct; the difference lies in the raw material, which delivers a significantly reduced climate impact.

Recycled steel

Recycled steel is a type of decarbonised steel that delivers approximately 60–65% lower CO₂ emissions compared to traditionally produced steel. It consists of at least 75% recycled material, while maintaining the same high-quality standards and properties as onventional steel. The steel is manufactured in electric arc furnaces powered by renewable electricity – ensuring the same performance, durability and guarantees, but with significantly less fossil resources used in production.

Recyclability is a cornerstone of the circular transition. Lindab therefore strives to increase the proportion of recycled content in our materials, and recycled steel is an important step towards that goal.

Environmental Product Declarations (EPDs) are available.

Savings example: Recycled steel

In new buildings, installation materials can account for 10–30% of the total climate impact. For renovations, the figure can rise to 50–80%. In both cases, the ventilation system alone contributes around 40%, and within that, duct systems account for about half.

By using circular and rectangular ducts made of recycled steel, the climate impact can be reduced by 60–65% compared to traditional steel, which is typically produced through Basic Oxygen Steelmaking (BOS) using blast furnaces.

Example: For a circular duct with a diameter of 125 mm, this corresponds to a saving of 2.44 kg CO₂e per metre (this refers to global warming potential – fossil).

Near-zero steel

Near-zero steel represents the next step towards fossil-free steel production. One example is SSAB’s fossil-free steel, produced using the HYBRIT process. In this process, hydrogen replaces coal and coke in the refining of iron ore. Renewable energy is used to extract hydrogen from water through electrolysis, and the by-product is pure water instead of large amounts of CO₂. The result is sponge iron, which is then melted in an electric arc furnace powered by fossil-free electricity – delivering steel with a dramatically lower climate impact.

Another example is SALCOS® from the Salzgitter Group, which replaces the traditional blast furnace route with direct reduction and electric arc furnaces. Lindab also has a seven-year supply agreement with Stegra (formerly H2 Green Steel), and a memorandum of understanding with Tata Steel Nederland for supplies of their Zeremis® near-zero steel once the IJmuiden steelworks transitions to hydrogen-based production.

Steel – a circular material

Steel is a key material in Lindab's products and plays an important role in the circular economy. It is durable, fire-resistant, and can be manufactured using recycled resources, making it an essential part of sustainable construction.

Key benefits of steel:

- Has a long lifespan

- Is fire-resistant

- Can be recycled again and again without loss of quality

- Can be manufactured using recycled resources

Recyclability is a cornerstone of the circular transition. Lindab therefore strives to increase the proportion of recycled content in our materials. By using decarbonised steel, we can offer products that combine durability with minimal climate impact.

FAQ