Steel to meet climate directives

According to the EU directive ‘Fit for 55’, greenhouse gases are to be reduced by 57 percent in Europe by 2030. With products in decarbonised steel, the quality and performance stay unchanged, but the environmental impact is significantly lower compared to traditional steel. Regardless of your project and needs, we can help you choose the right products, solutions and materials to reduce your own and your customers’ carbon footprint, without compromising on quality.

Same quality, less CO₂ emissions

Our whole range of ducts along with most fittings is available in recycled steel, meaning steel that consists of at least 75 percent recycled steel. During production it emits 60-65 percent less CO₂ than traditional steel but has the same high-quality standards and properties. In other words: the same performance, durability and guarantees but with a whole lot less fossil used in the making.

Be first with near-zero steel

Lindab works with a number of different steel companies across Europe to ensure proper access to steel that support the sustainable transition. Several of these producers are working on their own variants of what we choose to categorise as near-zero steel, i.e. virgin steel that has been produced with a minimal amount of fossil energy. At Lindab, we have secured deliveries from the start of production.

No energy wasted

Buildings account for 40 percent of the world's energy consumption and the EU is placing increasingly higher demands on energy-efficient buildings. Let’s not waste any more energy than we have to, with an airtight duct system and demand controlled ventilation we ensure effective energy use and optimal indoor air quality in the building. Productivity and well-being are increased, energy consumption is reduced!

>> About demand controlled ventilation

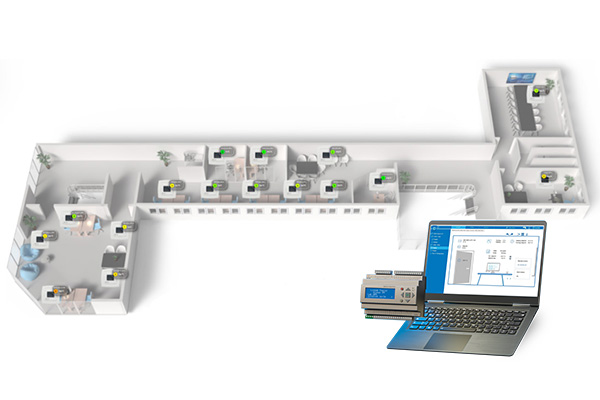

Turn old systems into demand controlled ventilation

Constant air volume systems are real energy wasters. They don’t have to be though, a case study of ours show you can keep 98 percent of an existing ventilation system and still get an impressive 68 percent long-term energy saving. The room control system Ultra BT is the optimal circular solution, upgrading an old ventilation system to a demand controlled system that can be installed in one room at a time. No reconstruction of walls, no long-term renovation shut down. Perhaps the easiest way to save energy in an existing building!

Utilize every watt to the max

Pascal System Management offers demand controlled ventilation, optimal for new construction or extensive renovations. Connect to the property's BMS system, with live status and full control of the ventilation system. Save up to 80 percent energy compared to a traditional constant air volume system and notice two things; people feel better, and you cut off a source that causes enormous amounts of untapped energy.

Minimal leakage, maximal effect

According to the European Commission’s renovation wave strategy, from 2020 we need to energy renovate 35 million buildings by 2030 in order to improve overall living standards for Europeans. With a leaking ventilation system, you use more energy for less air. An airtight air duct system is key to lowering energy consumption and Lindab Safe was the first air duct system in the world to be Eurovent certified with the highest tightness class D.

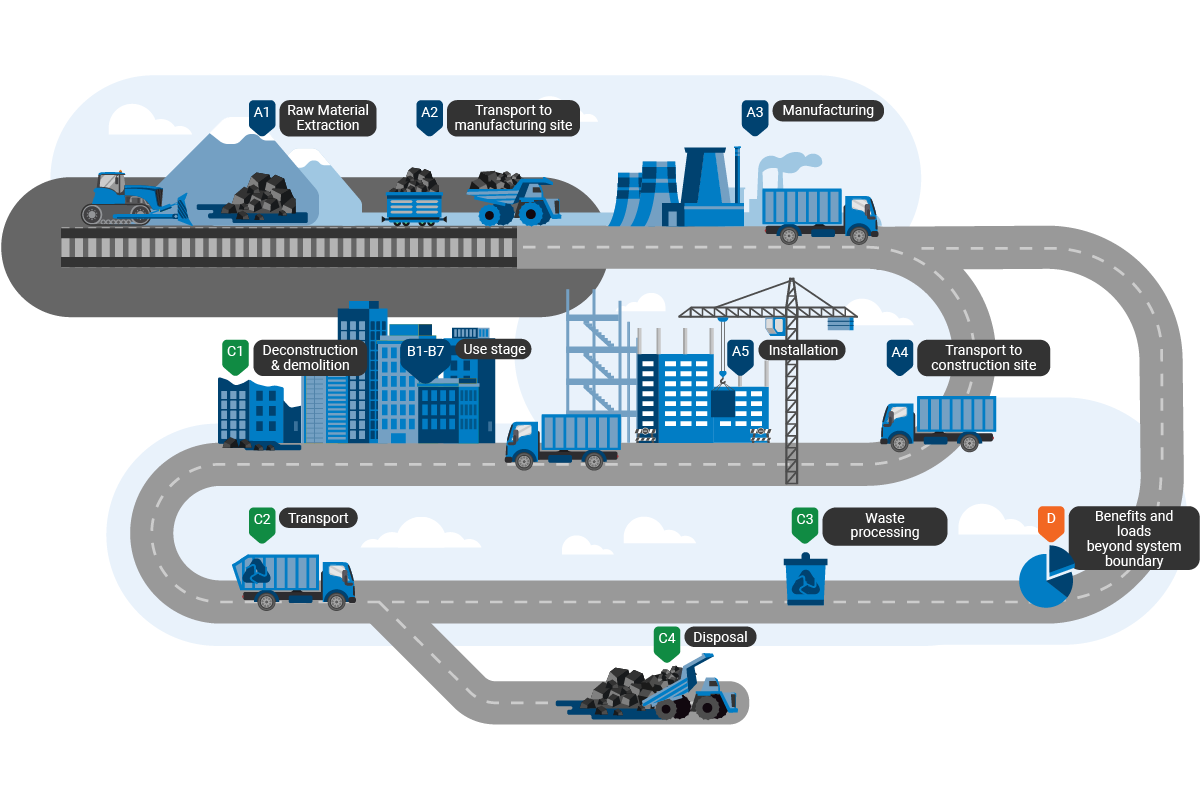

Verified environmental product declarations

Be sure to make truly informed product choices with the help of an independently verified environmental product declaration. The declaration takes the whole life cycle of a product into account, from raw material extraction through to manufacturing and end-of-life. It helps you fulfil life cycle assessments requirement stated in building certifications and climate declarations of buildings. For a better climate, both indoors and outdoors.

A better choice before, during and after

It’s important to consider the entire life cycle of a product or system so that your choice is not only climate-smart here and now, but over time. Everything from emissions in the manufacturing phase and installation, but also energy efficiency, lifespan and reusability. That is why we choose to use steel, which is both durable and recyclable. That is also why we provide Environmental Product Declarations showing the total climate impact of a product throughout its life cycle.

We practice what we preach

It’s one thing to talk about what we can help you with for a better climate, but what about ourselves? Well for starters we have a whole team of dedicated sustainability colleagues collecting and analysing data, implementing actions in our operations and making sure we are in line with our ambitious sustainability plan. Our emission reduction targets are approved by the Science Based Targets initiative which is the main international framework for science-based climate targets.

We have decreased our CO2e emissions by more than 40 percent in the last two years, 88 percent of our electricity consumption comes from renewable sources and emissions from purchased steel have decreased. We try to shorten transportation routes, offer on-site production solutions and try to use more reduced-emission transportation such as trains, renewable fuel, and electricity. This is a little of what has been done, and our intent is to do more. We are on the right track together!